#1 Raw Materials

The raw materials we mainly use to make plastic bottles are polyester (PET), polyethylene (PE), polypropylene (PP), PS (polystyrene), Acrylic (acrylic acid). After adding the corresponding organic solvent, after being heated at a high temperature, the plastic container is blown, extruded or injection molded through a plastic mold.

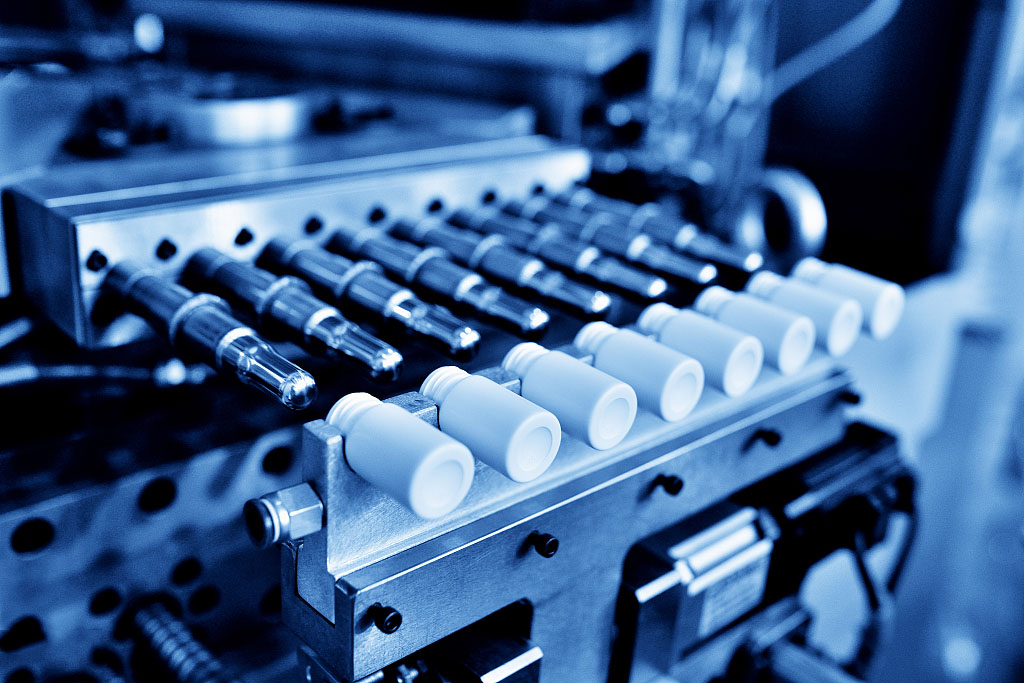

#2 Preforms

The raw PET pellets are poured into the injection molding machine through the pipeline, the auger in the machine pushes the pellets into the heating tube, the heating tube melts the PET pellets, and then the machine combs the liquid, injects it into the mold, and the mold is completed.

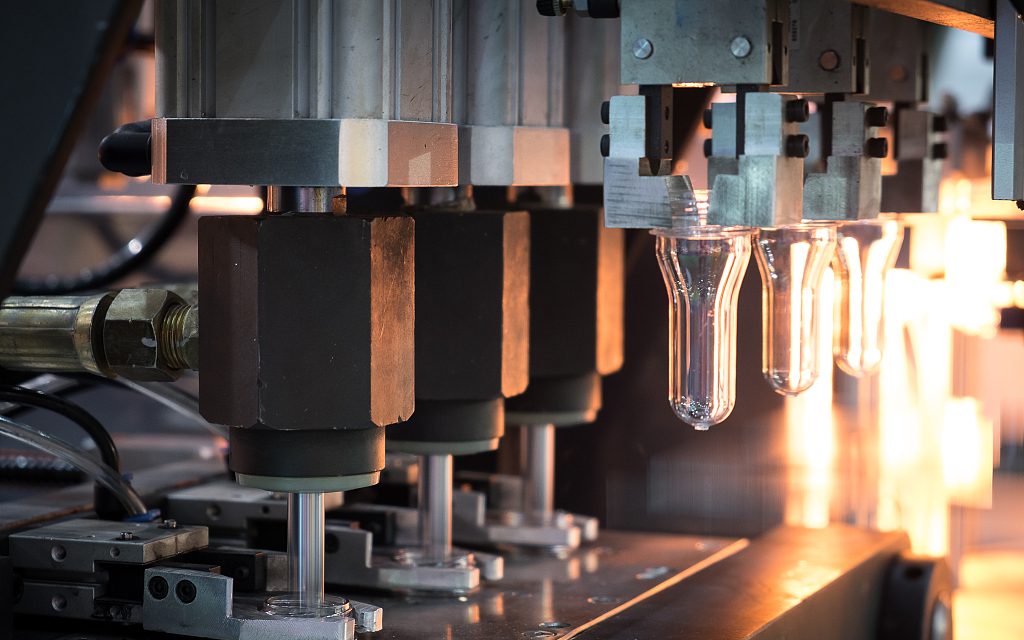

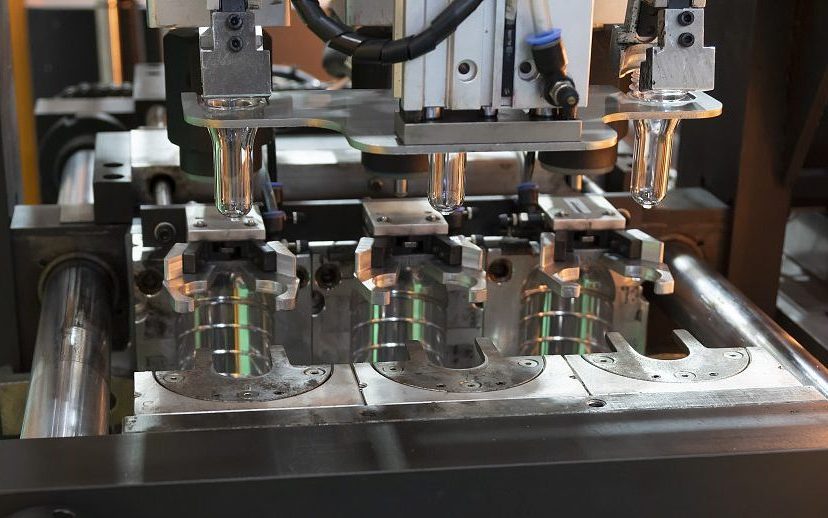

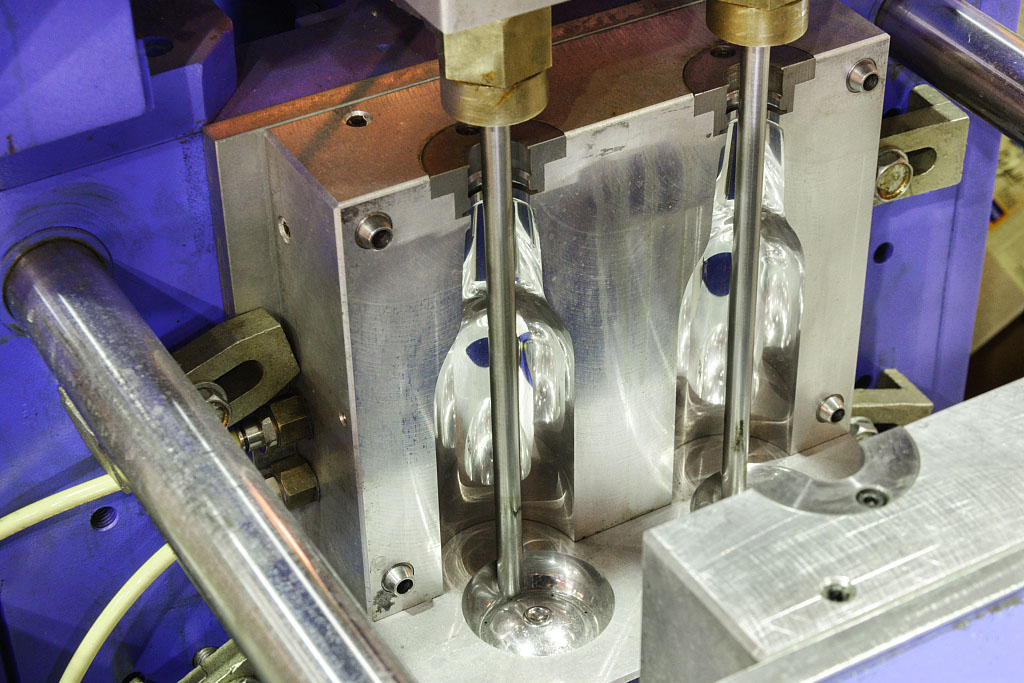

#3 Blow Molding

The preform is cooled, the preform is heated in a cycle, the gear at the mouth of the bottle is stuck, and the high-temperature preform is sent to the mold. At the edge, the ice water cools, the edge temperature of the mold is lower, and the bottle is formed through the cold metal.

#4 Injection Molding

It uses the thrust of the screw (or plunger) to heat the raw material, so that the plastic is melted in a flowing state and injected into the closed mold core. Driven by the screw or plunger of the injection machine, the injection system of the nozzle and the mold enters the mold cavity, and the product is obtained after drying and shaping.

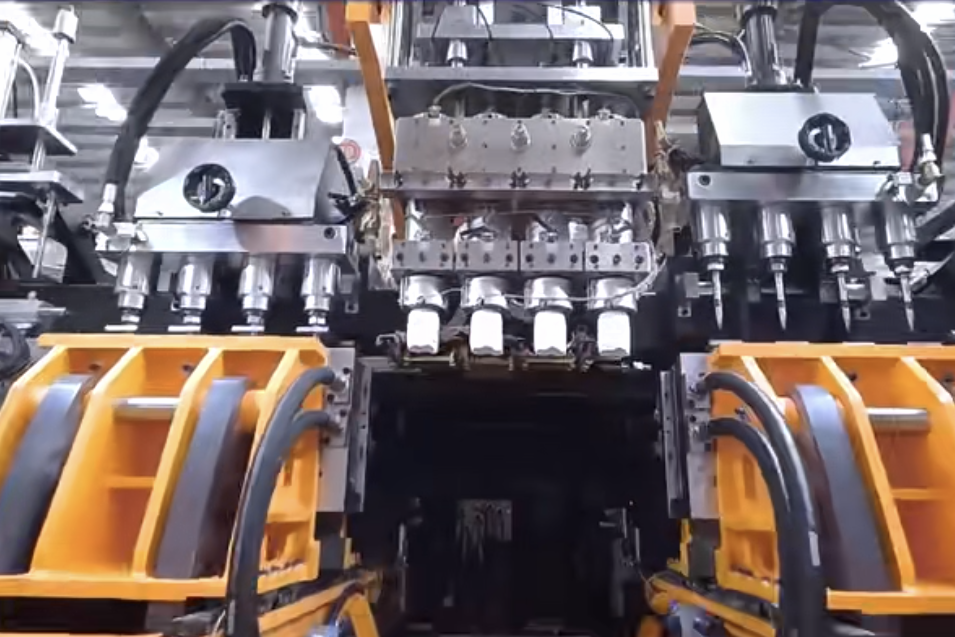

#5 Squeeze and Blow

Add the plastic raw material into the extruder, extrude the molten parison by heating, melting and plasticizing, and then put it into the bottle mold for inflation molding. , This process is mainly used to produce polyethylene PE.

#6 Injection Stretch Blow

The plastic raw material is injected into a tubular parison by an injection molding machine, and then put into a bottle mold for stretch blow molding, and the finished product is obtained after cooling. This process is mainly used to produce PET plastic bottles/product-category/plastic-bottles/.

#7 Quality Inspection

After taking photos for inspection and analysis, or regularly taking samples from the production line for quality monitoring testing, workers will test the strength of the bottle body through compression experiments according to the size and capacity of the sample, and evaluate the resistance of the bottle to vacuum pressure.

#8 Surface Treatment

Silk screen printing, Hot stamping, Silver printing.

After plasma surface treatment, it can increase the surface adhesion and adhesion of the bottle body, so that the spray-painted advertisement on the bottle body is more firm and does not fall off.